Biopharma processing

Oncological products and monoclonal antibodies (mAbs)

Overview

Overview

Oncological products, often referred to as cancer drugs or therapies, represent a critical frontier in the battle against cancer. The manufacturing process for these life-saving treatments is complex and highly regulated and it begins with extensive research and development.

Monoclonal antibodies or mAbs are antibodies designed to target specific antigens or molecules in the body that can help treat various diseases, including cancer and autoimmune disorders. They are created by cloning a single type of immune cell, known as a B cell, to produce large quantities of identical antibodies.

The manufacturing of oncological products involves several key steps, including: synthesis of Active Pharmaceutical Ingredient (API); formulation (the API is mixed with other ingredients, known as excipients).

Regulatory compliance is key: manufacturing processes must adhere to Good Manufacturing Practices and follow regulatory guidelines to ensure product safety and efficacy. Regulatory authorities like the FDA closely monitor and inspect these facilities.

This process also requires maximum attention to protect operators and the surrounding environment due to the high activity of the ingredients or high potent API.

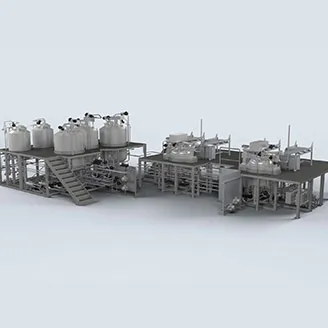

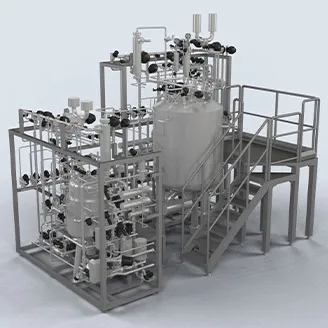

Olsa has extensive experience in offering proper and comprehensive process design and automation software management solutions, ensuring both the highest safety standard and also maximizing production efficiency.

Furthermore, Olsa collaborates with top-tier isolators Original Equipment Manufacturers (OEMs) to be able to deliver complete turn-key solutions.

Other Biopharma processing applications